…to

your professional RFID and AutoID service provider. You want to create a UHF RFID-based solution and are looking for expert advice, training or on-site support? Then you have come to the right place! With more than 15 years of experience in the AutoID business and over 25 years of experience in the automation industry, we have everything you are looking for!

You are a system integrator, machine or plant builder – Olaf Wilmsmeier will be happy to advise and support you in the realisation of your digitalisation project.

Are you looking for the latest standardization updates? Olaf Wilmsmeier is active in many standardization groups and can also advise you on these topics. We will be happy to inform you about the upcoming requirements of the Digital Product Passport through to the latest cybersecurity requirements of the European Union – and of course also about the latest news from the AIDC world.

Wilmsmeier Solutions proudly presents…

Do you know the current standards and future requirements?

As AIM’s delegate for standardization, I keep an eye on and actively shape current topics such as the newest EU driven cybersecurity requirements, Digital Product Passport and classic AIDC topics from ETSI, CEN/CENELC and ECC.

New Cybersecurity Rules for Radio Equipment

AutoID and OPC UA: key technologies for digitalization

Injection mould management

A challenging application that you can master with the right UHF RFID components. From tool recognition in the machine, the optimised repair and maintenance process to intralogistics, complex applications open up here. Knowing how, from physics to component selection, you will succeed in implementing a reliable solution.

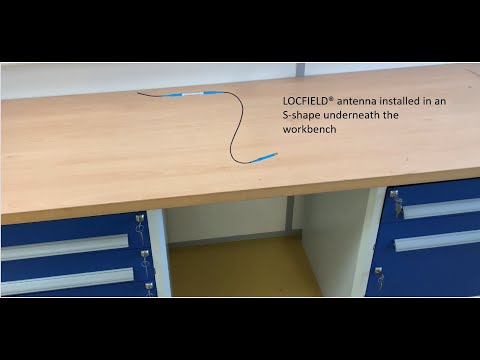

“Smart” workbench or “smart” shelf unit

Is the tool used calibrated? Display the current work plans automatically, matching the workpiece. Automatically recognise and inventory goods and load carriers on the shelf.

Such and similar tasks are easy to solve, especially with the right antenna. Often it does not have to be a special – and perhaps expensive – “smart shelf” antenna.

Intralogistics

It doesn’t always have to be the classic RFID gate with far-field antennas. Depending on the task, it is decided whether a forklift application, a local reading zone or the classic gate will lead to the right solution.

Train positioning and localisation

Automatic platform detection, positioning in front of screen doors on the platform side or localisation on the track. All of these have long been common UHF RFID applications. With the right application knowledge, the right components and the experience from around 20 projects worldwide, we will be happy to advise you on the implementation.

Train components and maintenance management

Which train is on which track in the maintenance hall? Which major components are installed? Were there any hot runners? These questions and more can be solved efficiently and automatically with the skilful use of UHF RFID. Of course, we are also happy to advise and support you with GS1-compliant marking.

RFID for SMT – Improving the overall life cycle management of electronic components

From raw PCB manufacturing to the recycling process, UHF RFID can improve the entire production, service and logistics process of electronic devices. It’s much more than just adding a unique ID to a PCB. Use the internal memory to pass important information directly with the product.

Digitalisation in hospitals

Digital inventory management, bed and equipment tracking, digital quality and test documentation – all this and much more can be realised by using Auto-ID technologies. Use your equipment efficiently, reduce search times, meet current requirements and standards for quality documentation.